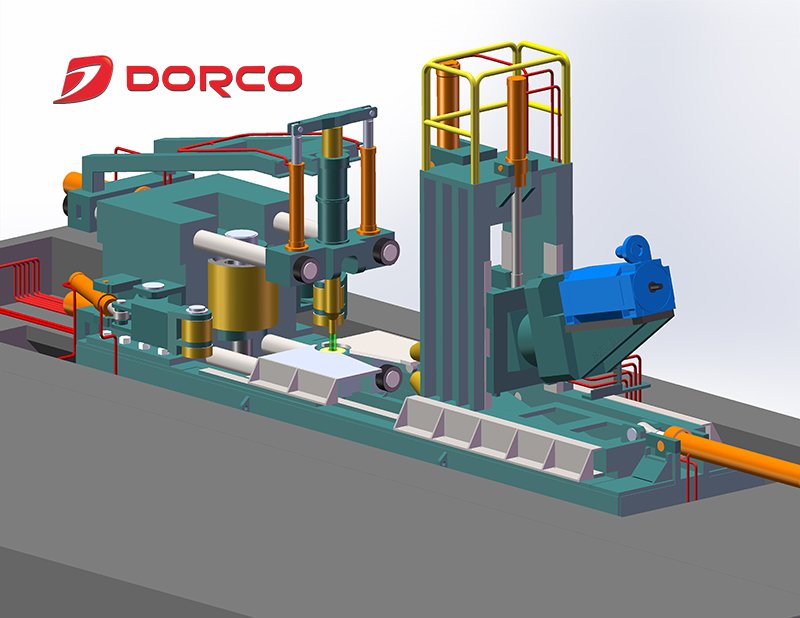

Dorco has customized a new radial-axial ring rolling machine based on user requirements. This machine is equipped with electro-hydraulic direct actuators mounted on the roll shafts, which, through a digital-to-analog conversion module, provide real-time control of the electro-hydraulic proportional valve, achieving precise control of the hydraulic cylinder stroke position. The machine obtains motion position feedback information via an encoder interface, representing an innovative drive solution in this application. Compared to traditional ring rolling machines, this design can reduce energy consumption by up to 40%.

The customer’s factory currently operates a small ring rolling machine, which in the future will be capable of rolling rings with a maximum diameter of 2,800 mm and a maximum height of 400 mm. The radial rolling force will reach 1,000 kN, and the axial force will reach 800 kN. Dorco will deliver this equipment in November, with a short delivery time and quick installation and commissioning being key advantages of this new machine.

Dorco’s ring rolling machine features both radial and axial composite rolling functions, making it ideal for processing large seamless rings. The customer stated, “We are deeply impressed by the cost-effectiveness of this newly customized ring rolling machine. We are confident that we will recoup our investment very soon.”

The investment cost of this ring rolling machine is about 20% lower than that of traditional ring rolling machines. Additionally, since it eliminates the need for a conventional central hydraulic system, there is no need to install related machinery and foundation piping. This not only brings economic benefits but also eliminates the risk of oil leaks causing environmental pollution. The ring rolling machine operates fully automatically based on CNC, using a digital control console, and requires only two electronic handwheels to complete the input of ring part and blank dimensions, automatically generating the rolling curve.

Yvonne.chu

Dorco Marketing Department